Introduction

Mechanical power transmission is a vital aspect of various industrial applications, enabling the transfer of power from one component to another within a machine or system. From simple belt drives to complex gear systems, efficient power transmission plays a crucial role in optimizing performance and ensuring smooth operations. In this article, we will delve into the world of mechanical power transmission, its key components, and highlight the importance of optimizing these systems for enhanced efficiency and productivity.

Understanding Mechanical Power Transmission

Mechanical power transmission involves the transfer of rotational or linear motion from a power source to different components within a machine. It is commonly used in industries such as manufacturing, automotive, aerospace, and many others. The main goal of power transmission is to transmit power while minimizing losses and maintaining the desired speed and torque.

Components of Mechanical Power Transmission

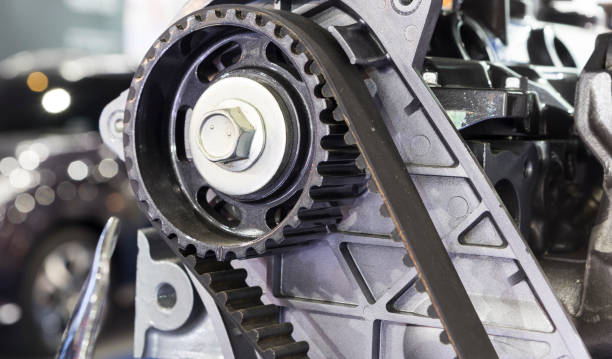

a) Belts and Pulleys: Belt drives are widely used for transmitting power between shafts that are not in close proximity. They consist of belts made of various materials, such as rubber or synthetic polymers, and pulleys that guide and transmit rotational motion. Optimizing belt tension, alignment, and selecting the appropriate belt type are crucial for efficient power transmission.

b) Gears: Gears are toothed wheels that transmit power between parallel or intersecting shafts. They provide speed and torque conversion while maintaining a constant rotational relationship. Proper gear selection, lubrication, and alignment are essential for minimizing losses and maximizing efficiency.

c) Chains and Sprockets: Chain drives are commonly used in heavy-duty applications, such as motorcycles or industrial machinery. They consist of interconnected links and sprockets that engage with the chain, transmitting power between rotating shafts. Maintaining proper tension and lubrication is vital for optimal chain drive performance.

Importance of Optimizing Mechanical Power Transmission

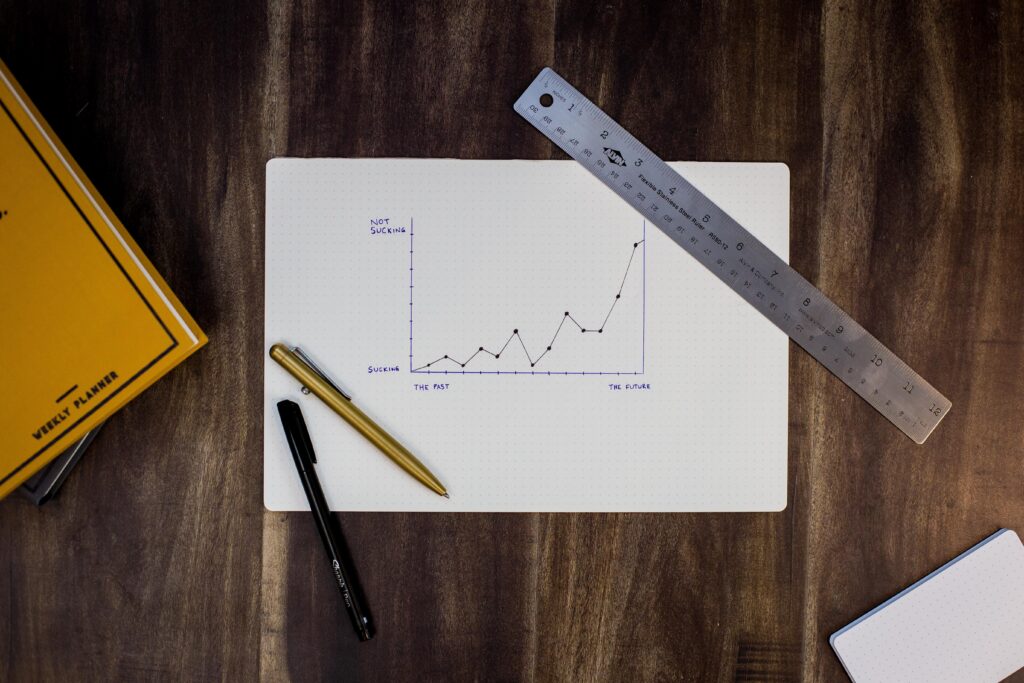

a) Efficiency: By optimizing mechanical power transmission systems, you can minimize energy losses and maximize power transfer efficiency. Proper selection of components, regular maintenance, and reducing frictional losses through lubrication and alignment can significantly improve overall system efficiency.

b) Performance and Reliability: Efficient power transmission directly impacts the performance and reliability of machines and systems. Well-optimized systems experience reduced wear and tear, improved response times, and smoother operation, leading to increased productivity and reduced downtime.

c) Cost Savings: Optimizing power transmission systems can result in substantial cost savings over time. Improved efficiency reduces energy consumption, leading to lower operational costs. Additionally, well-maintained systems experience reduced component wear, extending their lifespan and reducing replacement and maintenance expenses.

d) Noise and Vibration Reduction: Properly optimized power transmission systems minimize noise and vibration, resulting in a quieter and more comfortable working environment. This is especially important in applications where excessive noise and vibration can negatively impact worker safety and equipment integrity.

Conclusion

Efficient mechanical power transmission is essential for maximizing performance, reliability, and cost-effectiveness in industrial applications. By understanding the components involved and implementing optimization strategies such as proper component selection, regular maintenance, lubrication, and alignment, engineers can ensure smooth power transfer, reduce energy losses, and enhance overall system efficiency. Embracing optimization techniques in mechanical power transmission systems is a key step towards achieving higher productivity and operational excellence.